Surface Cleaning

Shot Cleaning

Surfaces which are blasted with conditioned or angular abrasives are cleaned and prepared for downstream coating processes. Descaling and deburring of cast or forged components, descaling and rust removal from steel profiles or the removal of old paint and other coatings are just a few typical examples.

Especially when angular abrasives are chosen, shot cleaning alters specific properties of the surfaces. It can be used to roughen brake pad mounts or roughen surfaces in preparation for a subsequently applied metallic coating, e.g. prior to galvanising.

David Schäder about:

KOTAR - The LC abrasive with the performance of an HC abrasive.

Beim Aufruf des Videos werden personenbezogene Daten (IP-Adresse) an den Betreiber des Videoportals gesendet. Daher ist es möglich, dass Zugriffe gespeichert und ausgewertet werden. Detaillierte Infos finden Sie in unserer Datenschutzerklärung.

Beim Aufruf des Videos werden personenbezogene Daten (IP-Adresse) an den Betreiber des Videoportals gesendet. Daher ist es möglich, dass Zugriffe gespeichert und ausgewertet werden. Detaillierte Infos finden Sie in unserer Datenschutzerklärung.

Our products

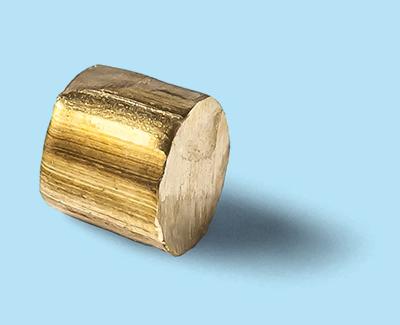

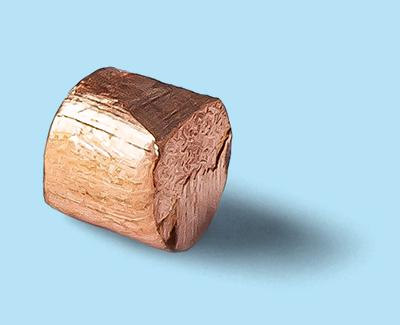

Blastex® is perfect for shot cleaning, deburring, desanding, descaling, cleaning: all the most important aftertreatment activities on cast or forged components are normally carried out using the proven shot-blasting wheel process. Blastex® by Krampeharex offers ideal material properties for this purpose and is available in all relevant materials.

High-quality basic material is used by krampeharex to obtain first-class abrasives with a precise geometry, preventing subsequent surface irregularities and ensuring excellent blasting results.

Suitable for a wide range of applications, cast iron abrasives offer cost-effective solutions. Whether conditioned or angular, low or high-carbon, at KrampeHarex you will find the right tool for your needs.

By using high-quality scrap grades, we guarantee top quality for the best blasting results.

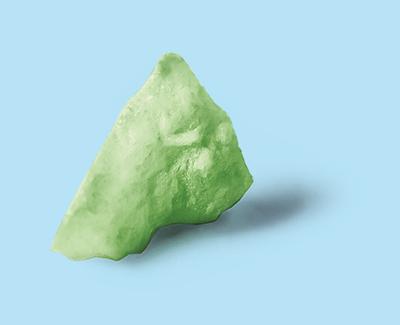

If particularly gentle processing of your component is required, the non-metallic blasting agents from KrampeHarex are used.

You will find the optimum solution for your specific needs, whether aerospace or medical technology, in our selection of iron-free blasting media.

Do you have questions

about our abrasives?

Contact us!

Your direct line

to KrampeHarex

Robert Hübner

Sales Germany South & Product manager