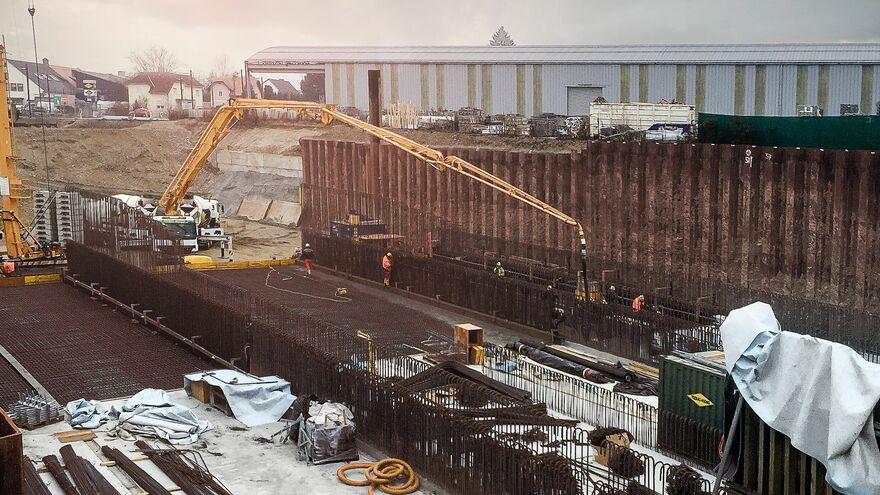

Lining segements, shotcrete, in-situ concrete

Sustainable and safe reinforcement

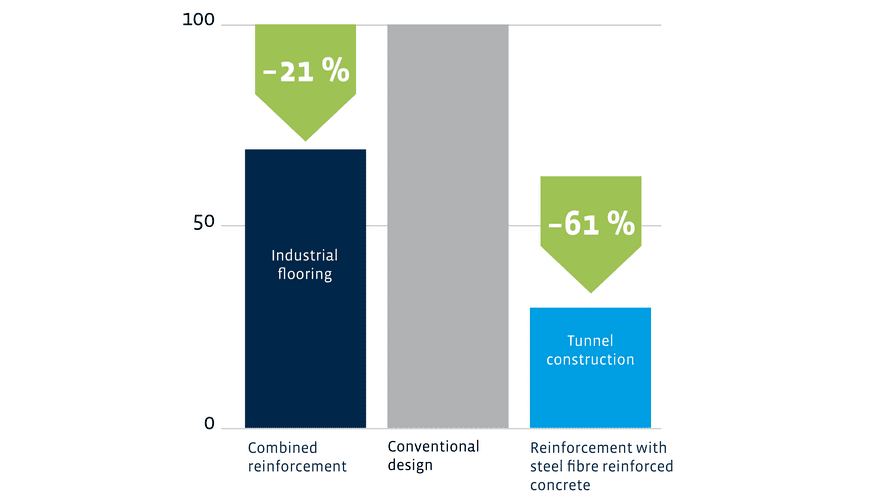

Reduction of the environmental impact through the use of steel fibres – comparison of construction and reinforcement types

Build tunnels with up to 61% lower environmental impact.

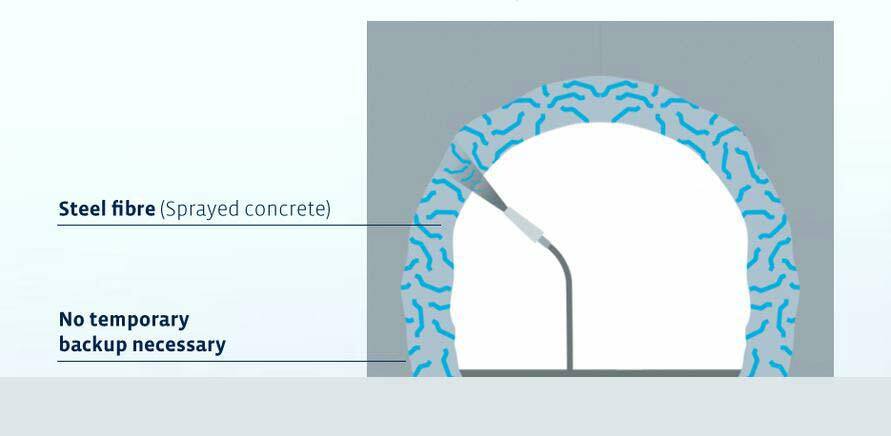

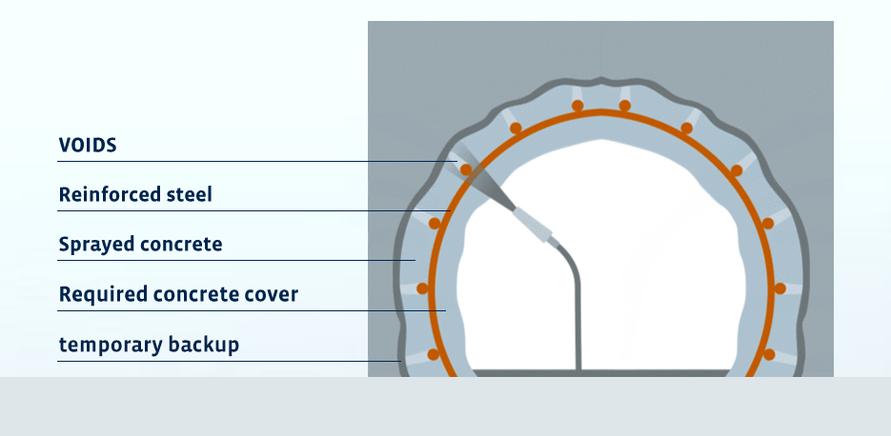

By replacing conventional rebar and reducing the Portland‑cement content, KrampeHarex steel fibres make tunnel linings significantly more resource‑efficient. The mechanical performance of the fibres enables robust, durable shotcrete structures with substantially lower material consumption and a noticeably smaller CO₂ footprint — from production to installation.

The environmental advantage is quantifiable:

the graphic shows the reduction potential of steel fibre‑reinforced tunnel construction compared to traditional designs.

Want proof?

Then take a look at one of our reference project

Lining segments

The advantages of KrampeHarex fibres

Reinforcement with fibres from KrampeHarex copes with these load conditions better than conventional reinforcement in the form of tubbing segments does.

Faster stripping of the lining segments

The tubbing segments can be stripped after just 6 hours. This increases production performance.

Space-saving storage

As the fibres are uniformly distributed in the components, up to 7 tubbing segments can be stacked on top of each other without any risk of breakage.

Transport with less damage

Thanks to the uniform distribution of the fibres, the tubbing segments are also more stable against vibration and impact shocks during transport.

High stability during installation

When installing with the aid of a tunnelling machine, high loads act on the components. Here too, the stability of fibre concrete is an advantage.

Extremely rugged

After installation, a wide variety of forces act on the tubbing segments. This is where fibre concrete proves to be extremely durable and resilient.

We let projects speak for themselves -

Case studies from the tunnel construction sector

Beim Aufruf des Inhalts werden personenbezogene Daten (IP-Adresse) an einen externen Anbieter gesendet. Daher ist es möglich, dass Zugriffe gespeichert und ausgewertet werden. Detaillierte Infos finden Sie in unserer Datenschutzerklärung.

Preventive fire protection has gained in importance in tunnel construction. New concepts demand that the concrete itself has a protective effect. This is made possible by adding synthetic fibres, because these reduce or prevent explosive concrete spalling.

Our polypropylene fibres are the result of many years of research and development. Their fire protection properties have been tested in collaboration with institutes like the Leipzig Institute for Materials Research and Testing (MPFA Leipzig GmbH), and the fibres have already been used in pilot projects like the Leipzig City Tunnel.

without PP fibres

with PP fibres from KrampeHarex

from a single source

Dosing and conveying technology

In the field of dosing and conveying technology, we offer tailor-made solutions for precise and efficient processing of PP and steel fibres. Our range includes conveyor belts, blow-in devices and automatic dosing systems that guarantee maximum accuracy and reliability.

In addition to standardized systems, we also develop special solutions that are individually tailored to your requirements. We take care of the professional installation and commissioning on site and ensure optimum dosing settings so that your processes run smoothly and efficiently.

Find the right fibre for tunnel constructions

The KrampeHarex Fibrefinder

Do you have questions

about our fibres?

Contact us!

Your direct line

to KrampeHarex

Wilhelm Nell

Business Unit Director Fibres