Project information

| Project: | Barrandov Bridge rehabilitation |

| Location: | Prague, Czech Republic |

| Application: | UHPC |

| Component: | UHPFRC bridge deck overlay from 25 mm thickness |

| Construction time: | 2020 - 2024 |

| Requirements: | Strengthening of the existing structure, structural sealing |

| Concrete: | UHPFRC ready-mix-concrete |

| Total volume: | 1,600 m³ concrete |

| Fibre type: | DM 14/0,175 |

| Dosage: | min. 3 Vol-% |

The Barrandov Bridge is one of the most important transportation structures in the Czech Republic. With a daily traffic volume of over 140,000 vehicles, it is the busiest bridge in the country. Since its commissioning in the 1980s, it has been in continuous operation for almost four decades. This intensive use led to considerable wear and tear, particularly on load-bearing components.

The comprehensive renovation of the bridge began in 2022. The renovation is divided into two main phases: In the first phase, the piers were refurbished between 2020 and 2021 without the need for major traffic restrictions.From 2022 to 2024, the bridge deck was repaired and widened, and the load-bearing structure was strengthened by external post-tensioning.

TBG Metrostav s.r.o. played a key role in this project as the specialized concrete partner. The company produced high-performance UHPC mixes tailored for the structural requirements, managed complex logistics for timely delivery, and executed precise on-site placement. With its expertise in innovative concrete solutions and its network of modern mixing plants, TBG Metrostav ensured the durability and safety of one of the Czech Republic’s most critical transport infrastructures.

Most sustainable fibre manufacturer.

Worldwide.

Our fibres perform significantly better than those of other manufacturers in terms of overall greenhouse warming potential. This is due to our integral approach, which requires the economic use of resources from the procurement of the raw material through to shipping of the fibres. In addition, we buy our electricity to 100 percent from renewable energy sources and produce a considerable share of our requirements ourselves thanks to our photovoltaic plant.

A central element of the renovation is the complete replacement of the road surface and the reinforcement of the supporting structure.

The project faced several challenges, such as unexpected roadway layer thickness and integrating the road level with adjacent ramps or insufficient load-bearing capacity of the bridge structure. To meet all requirements, a material suitable for application from 25 mm thickness had to be identified.

UHPC was selected because of its high strength and rapid construction. This enabled not only the leveling and widening of the existing structure, but also increased its load-bearing capacity and provided long-term protection of existing concrete structure.

UHPC or UHPFRC (Ultra-high-performance fibre reinforced concrete) has outstanding material properties to enable structures and architectural works of art that far surpass conventional concrete construction in terms of processing time, intricacy and durability.

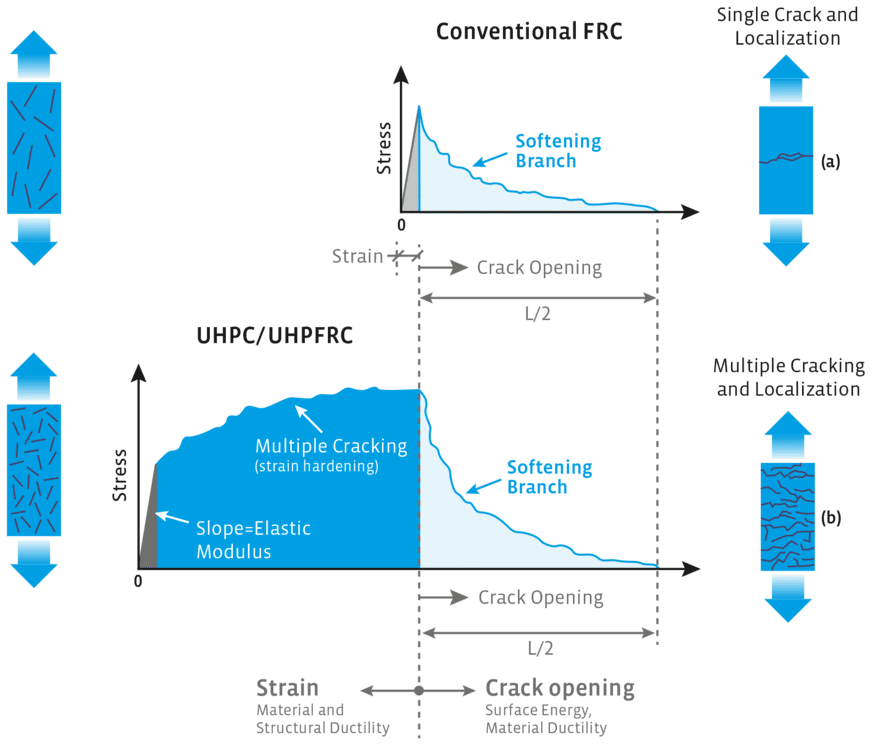

UHPC contains steel fibres between 1.5 % to 3 % of the total volume (120 kg/m3 and 240 kg/m3 ). The high micro steel fibre content to provide a strain-hardening behavior under tension and a ductile failure mode under compression. The relatively high content of steel fibres avoids a brittle failure when very high stresses under compression or bending are reached.

UHPC reaching 150 MPa under compression and showing a strain hardening load deflection behavior, a high packing density with a grain size of 5 mm and a water/cement ratio below 0.25.

KrampeHarex steel fibres guarantee these outstanding properties and make it possible to replace or reduce the reinforcement. Our stainless steel microfibres guarantee the structural and aesthetic properties and allow components to have a service life of 100 to 120 years.

Dr. Christian Neunzig

Technical Manager Construction Technology

A specially developed ultra-high-performance concrete called TopCrete® was used for the project. The formula was based on a combination of applicable European norms and internal standards, as no official national guidelines existed at the time of planning.

A key criterion for the choice of material was the ability to install the concrete on slopes of up to 6%. This required a targeted adjustment of the tixotropy in order to ensure stable placement despite the high proportion of superplasticizer. Equally important was the high content of steel microfibers - with a minimum proportion of 3 % by volume - in order to significantly reduce the crack widths and ensure the impermeability of the layer. DM 14/0.175 from KrampeHarex was the only choice for this project.

Do you have questions

about the project?

We look forward to hearing from you.

Your direct line

to KrampeHarex